A Background

Disc brake systems, centered on what is called brake rotors, originally emerged in 1898 during the design-build for Elmer Ambrose Sperry’s electric car. By 1908, Frederick William Lanchester refined Sperry’s original work and patented a system for that era’s consumer automotive market.

Between then and now, materials and technologies have evolved. DIY buyers can choose from more than just one option. Now there are a host of brands to pick from.

What Is A Brake Rotor?

Brake rotors rotate along with a vehicle’s axle. Rotors are slowed/stopped when calipers fitted with brake pads pinch or clamp down on them. (More about friction science here.)

Most consumer or commercial brake rotors are fabricated of metal or metal alloy. Although in specialized situations, rotors are crafted of exotic materials including carbon fiber.

How do brake rotor components improve your vehicle? We’ll tell you.

- Better design – Disc systems afford drivers more stopping power when compared to less sophisticated systems such as drum brakes. This is because of the increased braking surface offered by discs and the frictional dynamics provided by the caliper system.

- Reduced heat – Heat is bad for braking systems since heat-warping can limit frictional force. Disc systems are more effectively cooled across the rotor plane.

- Easier to maintain – Disc systems are simpler to deal with because there are fewer components and its easier to access the parts.

What Types Of Rotors Are Available?

Varying levels of performance can be expected from each type of brake rotor. These major categories include:

Smooth – This design offers excellent performance for daily driving needs. Advantages include a large rotor surface excellent for heat dissipation, resistant to cracking over time, rigid and dependable, and, in specialized cases, can be used for competitive purposes along with enhanced brake pads and fluids.

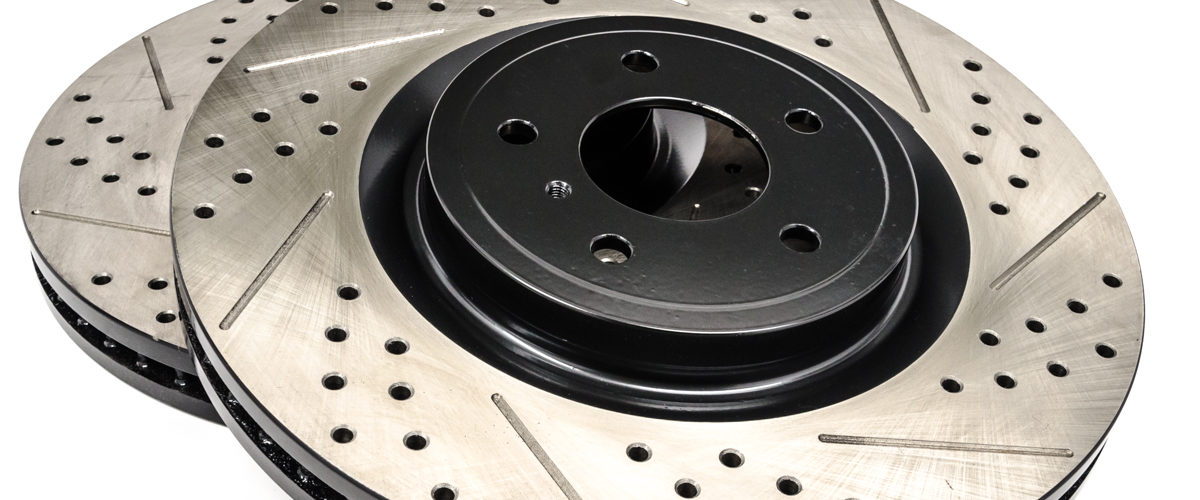

Slotted – This design provides enhanced performance over daily driver needs. Grooved surface results in better brake pad contact, enhanced heat dissipation, and reduced overall friction during heavy braking.

Cross-drilled – This design extends performance-oriented driving. Advantages include enhanced pad/rotor contact, aesthetic value, and reduced liquid adherence to rotor face, which allows for better braking in wet conditions.

Drilled and Slotted – This design offers excellent overall behavior, particularly in the case of heavy-duty use. Advantages include extended heat dissipation, durable, and dependable for high-weight towing or similar purposes, specifically valuable when mated with high-viscosity fluids such as DOT 3 or 4.

If you’re interested in any of the above-described brake rotors, take a look at the brands offered here on BuyBrakes.com.

If you’re not sure which rotors are right for your vehicle, contact us and we’ll walk you through it.