A brake booster is a component that multiplies braking force when the driver applies the brake pedal. This brings the vehicle to a stop with reduced foot pressure on the pedal. Before brake boosters, manual brakes required much more effort to press the brake pedal and stop the vehicle. A brake booster ensures maximum braking power is available with minimal pedal pressure.

There are a few different types of brake boosters in use today:

- Vacuum Brake Booster Systems

- Hydro-Boost Brake Booster Systems

- Electro-Hydraulic Brake Booster Systems

Read on for an explanation of each system type.

Vacuum Brake Booster

A vacuum type booster is the most common type found in passenger cars. Used on most gasoline-powered vehicles, a vacuum booster is mounted on the firewall between the brake pedal and the brake master cylinder. The booster is a metal chamber with a flexible diaphragm dividing both sides. Vacuum boosters are typically 6-8 inches in diameter, and 3-4 inches thick. Engine vacuum is supplied to both sides of the diaphragm until the brake pedal is pushed. As the pedal is applied, a metal rod pushes a valve against the diaphragm and allows atmospheric pressure to enter the pedal side of the chamber. With the master-cylinder side of the chamber still under vacuum, the difference in pressure creates the assistance or “boost” needed when applying the brakes.

In applications where engine vacuum is insufficient, a vacuum pump may be used to supply the vacuum needed for proper booster operation. Looking for a new vacuum brake booster? Find the right replacement part for your vehicle here.

Hydro-Boost

A hydro-boost brake booster is mounted on the firewall between the brake pedal and master cylinder, just like a vacuum booster. Instead of engine vacuum, hydraulic pressure is supplied by the power steering pump for braking assistance. As the brake pedal is pressed, a spool valve moves inside the housing and directs fluid pressure into a chamber. The force of the fluid in the chamber causes a piston to move forward and provide boost when applying the brakes. An accumulator stores pressure in the event that power steering pressure is lost.

Hydro-boost is used in applications where engine vacuum may be weak (supercharged or turbocharged engines) or not available (diesel engines).

Electro-Hydraulic

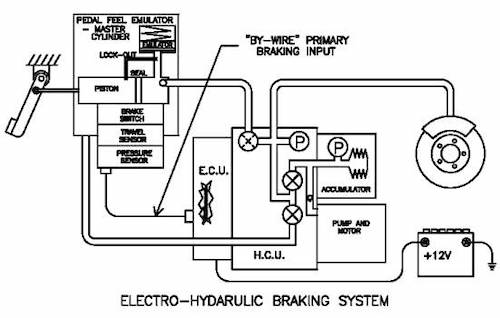

Electro-hydraulic boost is a newer type of braking assistance deployed on hybrid and electric vehicles. Referred to as “brake-by-wire”, there is no direct connection between the brake pedal and the brake system. The system is part electrical and part hydraulic. Sensors measure the amount of pressure applied to the brake pedal and send these signals to an electronic control unit (ECU). Using inputs from several sensors, the ECU determines how much brake pressure is needed at each wheel.An electro-hydraulic brake system combines the functionality of anti-lock braking and stability control into a single unit. The system also integrates with regenerative braking on electric cars. This occurs when the electric motor reverses to both slow the vehicle and recharge the batteries. Brake pedal input is used to determine if additional hydraulic assistance is needed to stop the vehicle.

While vacuum and hydro-boost brake boosters have been common for decades, they may gradually be phased out in favor of electro-hydraulic systems for more precise control of braking and integration with vehicle safety systems.

Need to replace or upgrade your car’s brake booster? BuyBrakes is here to offer the best prices on replacement brake boosters for your vehicle. We offer both vacuum and hydraulic boosters, depending on your make on model.